The content of the article:

- Design features of a gasoline engine

- Performance Indicators

The overwhelming majority of modern cars are equipped with gasoline engines, which makes it especially important to know all its advantages and weaknesses. This will allow you to adjust the mode of its operation, as well as carry out routine maintenance on time, which, ultimately, will have a positive effect on the duration of the engine's proper operation.

Design features and their impact on the main indicators of a gasoline engine

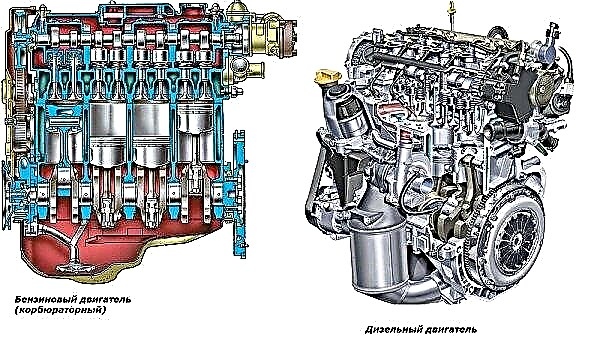

Motorists prefer a gasoline engine due to its low cost, relative simplicity of design, and lower weight. These factors are primarily due to the design features of such a unit.

The principle of operation of a gasoline engine is based on the ignition of a previously prepared fuel-air mixture with the help of a spark produced by spark plugs. In this case, the compression ratio generated in the combustion chamber is relatively small and ranges from 8 to 12 units. This is what makes a gasoline engine significantly lighter than its diesel counterpart, in which increased loads necessitate the use of parts with a large margin of safety.

Moreover, now on modern cars, the technology for the production of an aluminum cylinder block has actually received a second wind, which was practically abandoned in the 80-90s of the last century.

As another mechanism for reducing the total mass of the engine, the abandonment of steel liners in the cylinders in favor of a special cermet wear-resistant layer is widely used. To the great regret of car owners, many of the engines built using this technology cannot be overhauled, the need for which may arise not only due to long-term operation, but also due to the use of low-quality fuel.

Modern trends in the automotive industry provide for the active introduction of turbocharging on gasoline engines, which makes it possible to further expand their operating range, as well as raise traction at low revs. The negative side of this solution is a significant increase in the cost of the unit as a whole, as well as the need for more expensive and frequent maintenance.

As for the specific efficiency, which is at a fairly high level in gasoline engines, constant work aimed at its growth, to some extent, negatively affected the durability and maintainability of the unit as a whole. First of all, it is about reducing the mass of the piston group to reduce internal losses.

This is a fairly effective measure for increasing power density and improving efficiency, but its downside is increased oil consumption and the need to use expensive alloys that could provide the proper degree of wear resistance for small contact areas.

The next area of work on modern gasoline engines is to optimize the combustion chamber and increase the compression ratio. These measures have led to the fact that the engines have become extremely sensitive to the quality of the motor fuel used, and the slightest malfunction in the gas distribution mechanism inevitably leads to overhaul, if not the entire engine as a whole, then its cylinder head. This situation has become widespread also in connection with the rejection of the use of metal chains in favor of belts in the drive of the gas distribution mechanism.

Thus, activities aimed at improving the efficiency of gasoline engines allow obtaining high power indicators with a sufficiently low fuel consumption, but at the same time negatively affects the resource and maintainability of this expensive unit.

There is an opinion that a gasoline engine is capable of converting no more than 20-30% of the energy released from fuel combustion, while for a diesel engine this figure is 30-40%, and with the use of a turbocharger and an intercooler - up to 50%. This is partly true, but with the trend towards higher compression ratios for gasoline engines and lower compression ratios for diesel engines, as well as the widespread use of supercharging, the difference in efficiency is significantly reduced.

The best traction characteristics of a diesel engine in comparison with a gasoline engine are due to its design features, in particular, the fact that it does not have a throttle valve and the power is controlled by limiting the supply of diesel fuel. This has both pros and cons. On the one hand, the pressure in the cylinders remains unchanged, regardless of the driving mode, which ensures high traction characteristics in the low speed range, and on the other hand, this implies intense loads on the engine parts.

The design features of a gasoline engine open up quite ample opportunities for its modification. In particular, it is much easier to convert it to alternative fuels such as propane-butane or methane. The most important thing with such alterations is that the engine does not lose its ability to run on gasoline, which makes it bi-fuel. As for the diesel engine, such a modification is fraught with a complete transition to gas, since the principle of operation of the ignition system changes.

Performance Indicators

A distinctive feature of gasoline engines compared to diesel engines is that they reach maximum power at high revs, which allows you to easily maintain intensive acceleration in a very wide tachometer range, even without using turbocharging. This kind of work is very well suited for small cars that are operated with low loads, mainly on suburban roads.

This is also where the main disadvantage of gasoline engines is manifested - weak traction at low revs, which makes it difficult to start driving with a significant slope of the road, as well as with a high load.

This forces the motorist to start at higher speeds, which negatively affects the resource of the clutch mechanism.

Considering fuel consumption, then in the optimal mode of operation it will be very small. Unfortunately, the specifics of modern traffic makes economical driving a rare exception. So, a gasoline engine is very sensitive to loads, and if the car's interior is full or there is a heavy load in the trunk, then fuel consumption increases dramatically.

The same applies to the urban driving mode, which can increase this indicator by 1.5 times in relation to the base value. In fact, this nature of work makes the gasoline engine not very suitable for installation in SUVs and commercial vehicles.

A significant advantage of this type of fuel is its immunity to weather conditions - even in severe frost, a gasoline engine (if it is fully functional) does not need additional additives, which cannot be said about a diesel engine.

If we consider this aspect in the context of winter operation, then the gasoline engine is not only easier to start, but also requires much less time to warm up, which makes it possible to heat the interior just a few minutes after starting.For a diesel engine with a sufficiently large car interior, it may be necessary to install an auxiliary heater.

An equally important performance indicator of a modern motor is the level of its noise and vibration... According to this indicator, a gasoline engine clearly outperforms a diesel engine, in which the mixture is ignited under enormous pressure, releasing a large amount of energy, which leads to strong vibrations and the appearance of a characteristic rumble, which is almost impossible to drown out either by effective noise insulation or by using expensive dampers.

Also, for cars with a manual transmission, when equipped with a diesel engine, the switching frequency increases significantly, which in urban conditions can reduce the attractiveness and convenience of such transport.

Concerning security, then gasoline is much more fire and explosive, therefore, when operating such a car, increased attention should be paid to the tightness of the fuel system, the serviceability of electrical equipment.

It is also necessary to take into account the fact that even gasoline vapors are highly flammable (which is why it is forbidden to store this fuel in poorly ventilated rooms).

If speak about requirements for fuel quality, then gasoline engines are unconditionally preferable here, since despite the complication of their components and control systems, many of them can still digest gasoline with a lower octane number practically without loss.

As for the legendary unpretentiousness of diesel engines, then it has sunk into oblivion along with their atmospheric modifications. Modern high-pressure fuel pumps and injectors simply become unusable when trying to fill in low-quality fuel containing additives.

The quality of domestic diesel fuel is such that many automakers specifically make a number of design changes to cars that allow them to run on lower-quality fuel, or even refuse to supply diesel engines to our country.

This fact should be taken into account when buying a car that has never been officially delivered to Russia, or when purchasing a used car from the USA, Europe or Japan. Most modern diesel models are very demanding on the consumables used, in particular on fine fuel filters, which necessitates their frequent replacement. Moreover, the stability of its operation depends much more on the degree of their clogging than that of a gasoline counterpart.

Maintenance cost gasoline engines are also significantly lower than their diesel counterparts, as a result of which many believe that buying such a car will subsequently allow significant savings. In addition, the service interval of a diesel engine is almost twice as short, which predetermines frequent visits to the service.

As for the service itself, light diesel engines in our country were practically not mass-produced, motorists got to know them only thanks to imports. The same fully applies to service centers, where it is not always possible to find a qualified technician specializing in the repair of diesel units.

As for the traditional opinion that diesel engines are significantly more economical, given the almost equal cost of high-octane gasoline and high-quality diesel fuel, this fact, especially for a passenger car, is questionable.

In addition, the high initial cost and high maintenance costs further reduce the difference in operating costs. Thus, it is advisable to use diesel in commercial vehicles, as well as in cars with high annual mileage.

Conclusion

All of the above allows us to formulate the main advantages of a gasoline engine:

- relative constructive simplicity;

- significantly less weight;

- low price;

- the ability to develop high turnovers;

- relative ease of repair and maintenance;

- less noisy, compared to diesel, work process.

The main disadvantages of such a motor:

- high fire and explosion hazard due to the specificity of the fuel;

- an urgent need to use only high-quality oils;

- increased fuel consumption at high loads;

- weak traction and torque at low revs.

Thus, taking into account the above factors, an objective conclusion should be made that both gasoline and diesel engines have both advantages and disadvantages that delimit the appropriate areas of their application.